Robotic Initiative Continues to Compute at Dan Daniel

After the successful launch of phase one the $1.3 million Logistics Autonomous Robotic Initiative (LARI) at the Dan Daniel Distribution Center in December, phase two is now operational and going just as smoothly.

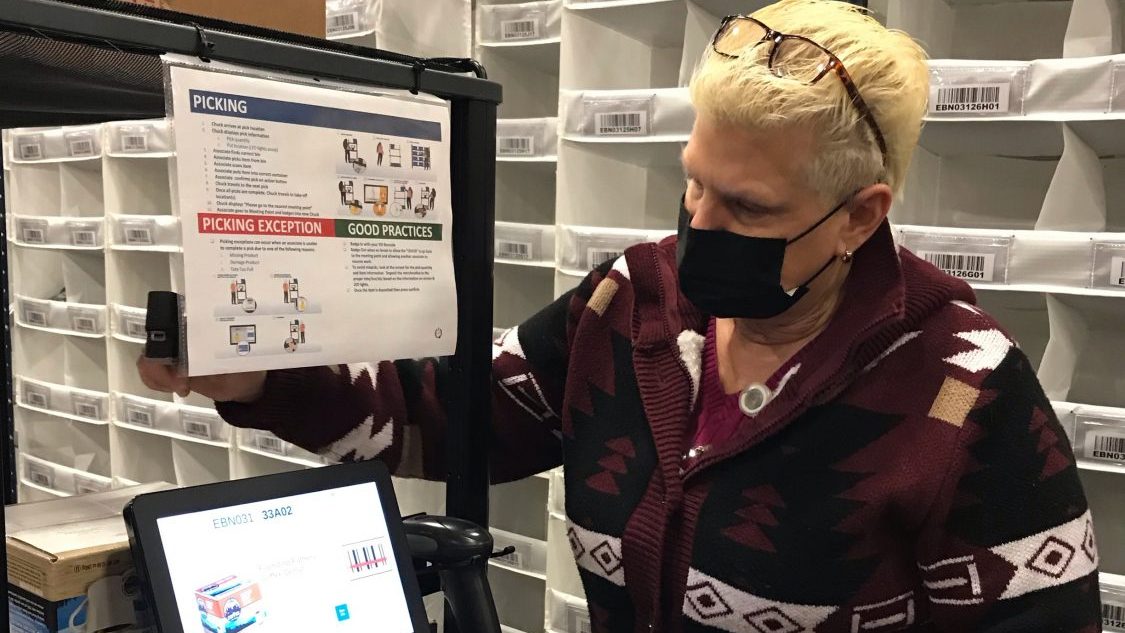

Shelly Reinert, Logistics operations manager at Dan Daniel Distribution Center, uses a robot to aid in restocking inventory.

Phase two, launched Feb. 28, focuses on restocking and the ability to print shipping labels as associates induct work onto the robots.

“The replenishment process has been an easy concept for the associates to transition to,” said Shelly Reinert, Dan Daniel operations manager. “Using the new slotting logic and having it robotic-driven is engaging for associates on the floor.”

The robots direct associates to picking/stocking locations, so that associates don’t have to be intimately familiar with the warehouse layout to find a product. Because the robots eliminate pushing and pulling of carts, associates undergo less physical strain. The robots also reduce the risk of mispicking items, and eliminate the use of hand scanners, which added extra time to the picking/stocking process.

“Because we have a logical map that we loaded into the robot solutions, the robot knows the warehouse layout,” said Linh Ngo, IT’s director of supply chain and Logistics Enhanced Distribution (LED) programs. “So the robot goes to the location, stops, and tells the associates what they need to pick or put away.”

Phase one of the project, which was more than a year in the making, went live Dec. 6 and has helped increase productivity while assisting warehouse associates with order fulfillment.

From early phase one data, Logistics projects a savings of more than $591,000 during fiscal 2022. Productivity for DC associates is expected to more than double, with a projected five-year benefit of $5 million.

“Phase one has been going really, really well,” Ngo said. “We’ve been monitoring the productivity since we implemented it and, on average, associates are able to pick about 120 units per hour, compared with 28 units per hour before the robots.”

The project is a collaboration among IT and distribution center teams, as well as others in Logistics. In December, senior IT and LG leaders presented 13 associates with certificates of recognition for their role in ensuring LARI’s smooth launch.

“Coming from the LED team and knowing what it takes to have successful projects, these have been two of the smoother go-lives,” Reinert said. “Credit to the teams involved for doing such a fantastic job and communicating our needs as an operation.”

This is the first time I see AAFES caught up with the latest technology so fast. Very exciting!